Guys, we did it! We opened a cidery and it only took us 2.5 years!

Now that we’re open, our focus has changed from fundraising, seeking legal counsel, location hunting, permitting, and general contracting to managing daily operations. These are the things we’re focusing our energy on these days:

1. Staffing. Up until May of this year, we were a pretty lean operation of me (Andrea) keeping everything moving and Aaron helping out with production and overall business decisions on nights and weekends. In May we hired our first employee, Joseph, as an Assistant Cider Maker. He put in long hours leading up to our opening to make sure we had cider ready, kegs were cleaned of all the little tiny rust spots that settled in from unloading them in the rain and not wiping them off (my bad), and improving the efficiency of the production process. Then we hired Melissa to run our tasting room and kitchen, who helped create our menu, made sure we had everything we needed to run a retail storefront, and taught me about standard serving practices. Finally, we hired Wes to make sure every customer is treated well in the tasting room and to turn visitors into regulars.

My job has changed from creating job descriptions and making hiring decisions to worrying about whether our employees like their jobs, are getting enough hours, and are as excited about the future of Ash & Elm as we are. For the record, I’m pretty sure we lucked out with each of them, but I still spend a lot of time thinking about how to make sure they are all getting out of Ash & Elm what they hoped to when they signed on to this crazy ride.

The whole team! From left to right: Joseph, Wes, Aaron, Andrea, and Melissa

2. Distribution. A lot of folks have asked when they can get our cider from bars and restaurants. Of course, there’s a short and a long answer. The short: ‘Soon, hopefully!’ The long: The state alcohol permit we need to make and sell cider (a Farm Winery permit, for those interested) doesn’t allow self-distribution. Which means I could have bars and restaurants with checks in hand waiting to put our cider on tap, but legally I can’t sell it to them. Instead, I have to sell the cider to a distributor, who would then sell it to the bar.

Fun fact! Our tasting room is on the ground floor of a three story building, and our Farm Winery permit only covers the first floor. If one of the businesses operating on the top two floors wanted cider, we would have to sell it to a distributor, who would then have to drive 10 miles away to their warehouse, who would then have to load it back up and bring it back to our building to sell to the top floor. Silly laws.

We have had meetings with multiple distributors, and our goal is to have that relationship lined up and going by the end of summer. Hang tight, we’ll get there, and we’ll make sure you all know about it!

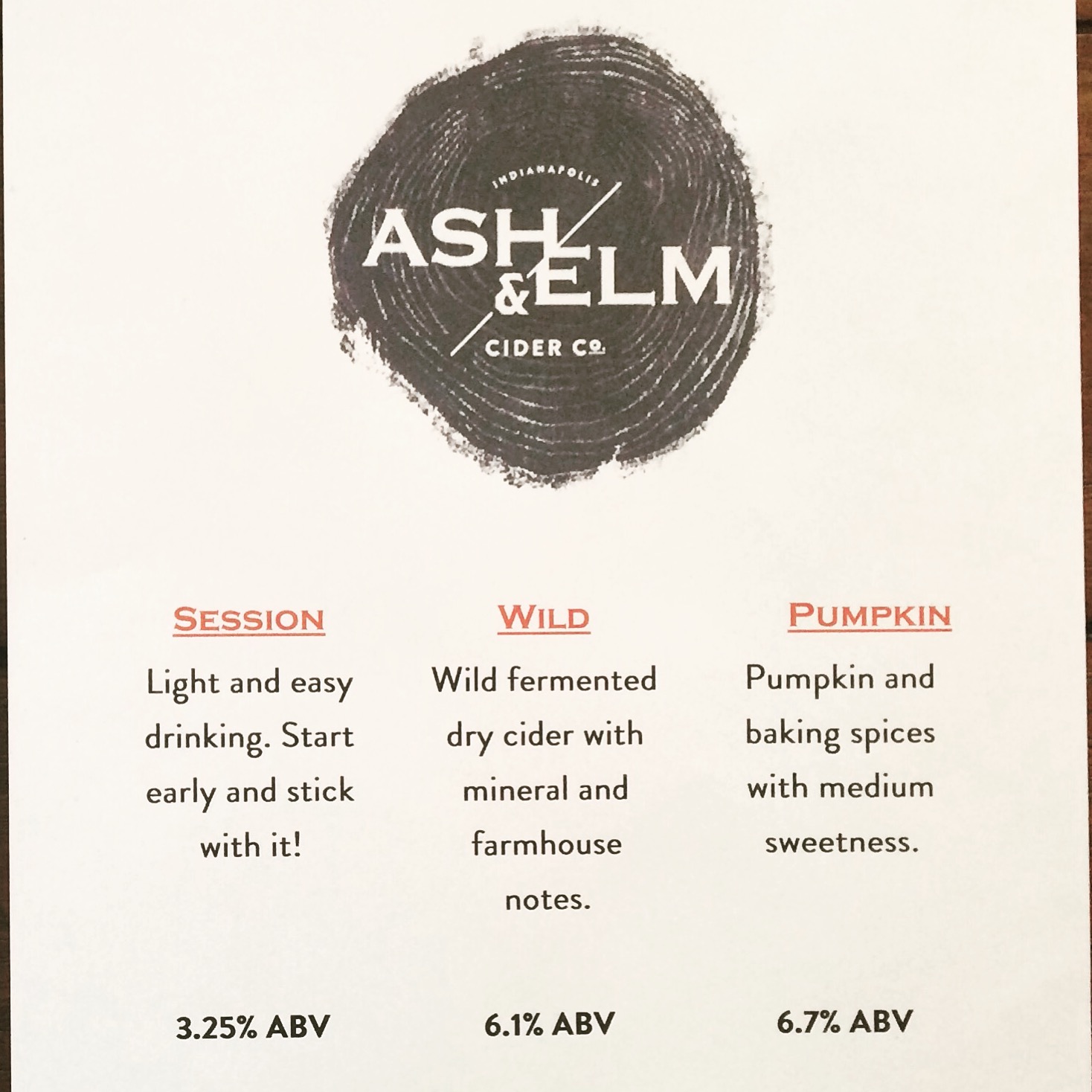

3. Getting the word out. Our tasting room has been open for three weeks now. A lot of my focus is shifting to marketing, sales, and promotions. In the short term, that will happen via events in the tasting room and participation in festivals throughout the city. Longer term, that means pounding the pavement to get bars and restaurants to buy into our product (see #2 on why that hasn’t happened yet). New menu options, seasonal ciders, consistency, and sponsorships/partnerships are always on my mind as avenues to explore as we grow our business.

4. Data Crunching. If you know Aaron and me, you know that we both LOOOOOVVVEEE data and Excel. Fun fact #2! Aaron is an electrical engineer, and I have a Master’s in Public Health with a concentration in epidemiology, so using data to predict the future gets us more excited than it really should. Anyway, now that we actually have tasting room sales and numbers, we can start crunching data. How much on average does a person spend in the tasting room? How many ounces of cider does the average customer drink, and how much does that increase if the customer also orders food? Which ciders are selling the best, and given sales in our first month, can we predict what our annual sales might be? When does it make sense to add another employee?

Truly, it is so nice to be open after such a long time. Transitioning from ‘starting’ to ‘managing’ has been invigorating. Thanks for joining us for the start-up phase of the business, and I hope you continue to enjoy the ride!